The batteries of electric vehicles subject to the normal use of real-world drivers – like heavy traffic, long highway trips, short city trips, and mostly being parked – could last about a third longer than researchers have generally forecast, according to a new study by scientists working in the SLAC-Stanford Battery Center, a joint center between Stanford University’s Precourt Institute for Energy and SLAC National Accelerator Laboratory. This suggests that the owner of a typical EV may not need to replace the expensive battery pack or buy a new car for several additional years.

Almost always, battery scientists and engineers have tested the cycle lives of new battery designs in laboratories using a constant rate of discharge followed by recharging. They repeat this cycle rapidly many times to learn quickly if a new design is good or not for life expectancy, among other qualities.

This is not a good way to predict the life expectancy of EV batteries, especially for people who own EVs for everyday commuting, according to the study published Dec. 9 in Nature Energy. While battery prices have plummeted about 90% over the past 15 years, batteries still account for almost a third of the price of a new EV. So, current and future EV commuters may be happy to learn that many extra miles await them.

“We’ve not been testing EV batteries the right way,” said Simona Onori, senior author and an associate professor of energy science and engineering in the Stanford Doerr School of Sustainability. “To our surprise, real driving with frequent acceleration, braking that charges the batteries a bit, stopping to pop into a store, and letting the batteries rest for hours at a time, helps batteries last longer than we had thought based on industry standard lab tests.”

A pleasant surprise

The researchers designed four types of EV discharge profiles, from the standard constant discharge to dynamic discharging based on real driving data. The research team tested 92 commercial lithium-ion batteries for more than two years across the discharge profiles. In the end, the more realistically the profiles reflected actual driving behavior, the higher EV life expectancy climbed.

Several factors contribute to the unexpected longevity, the study finds. A machine learning algorithm trained on all the data the team collected helped tease out the impacts of dynamic discharge profiles on battery degradation.

Real driving with frequent acceleration, braking that charges the batteries a bit, stopping to pop into a store, and letting the batteries rest for hours at a time, helps batteries last longer than we had thought.”Simona OnoriAssociate Professor of Energy Science and Engineering

For example, the study showed a correlation between sharp, short EV accelerations and slower degradation. This was contrary to long-held assumptions of battery researchers, including this study’s team, that acceleration peaks are bad for EV batteries. Pressing the pedal with your foot hard does not speed up aging. If anything, it slows it down, explained Alexis Geslin, one of three lead authors of the study and a PhD student in materials science and engineering and in computer science in Stanford’s School of Engineering.

Two ways to age

The research team also looked for differences in battery aging due to many charge-discharge cycles versus battery aging that just comes with time. Your batteries at home that have been sitting unused in a drawer for years will not operate as well as when you bought them, if they work at all.

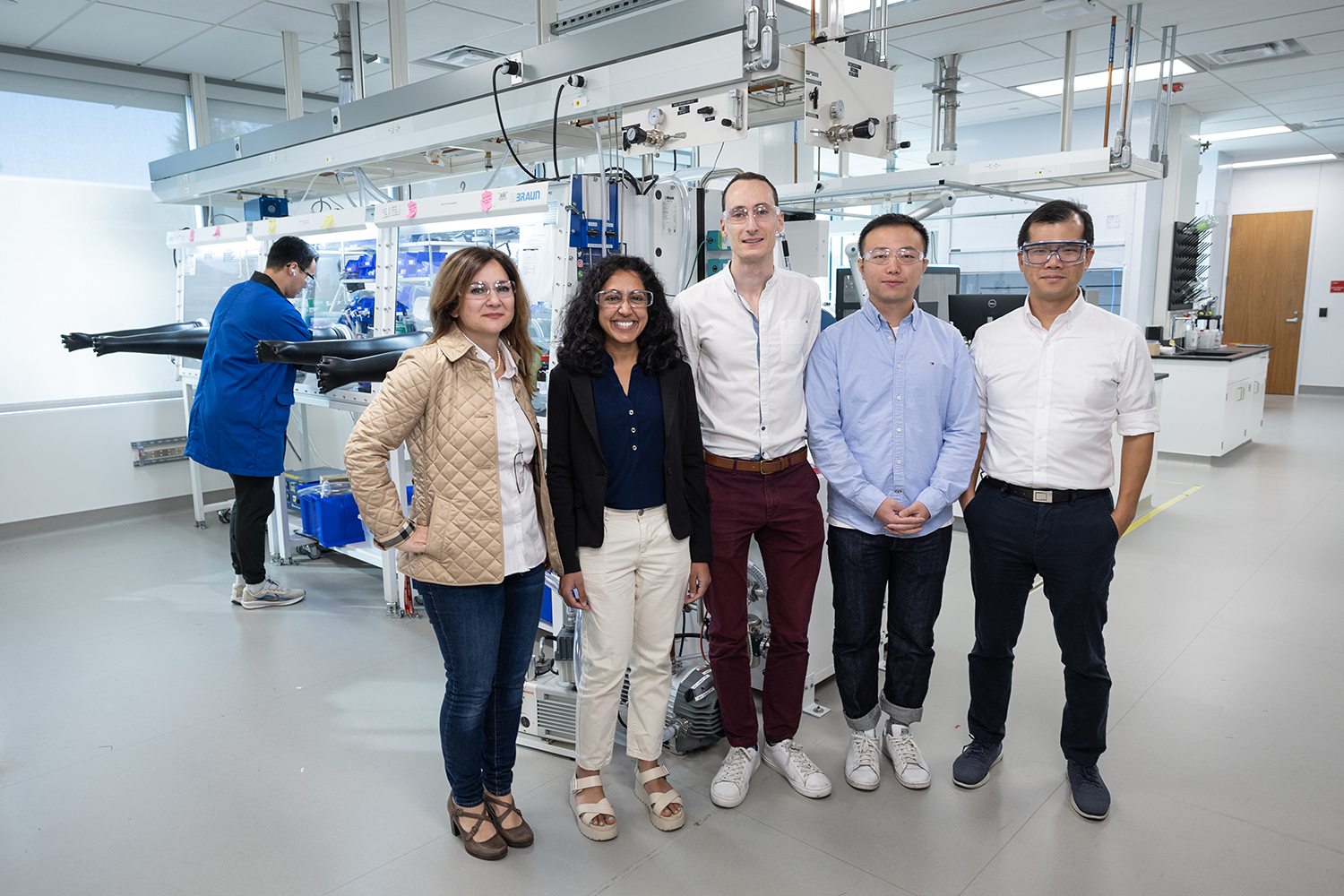

From left, Simona Onori, Devi Ganapathi, Alexis Geslin, Le Xu, and William Chueh in the SLAC-Stanford Battery Center. | Jim Gensheimer / SLAC National Accelerator Laboratory

“We battery engineers have assumed that cycle aging is much more important than time-induced aging. That’s mostly true for commercial EVs like buses and delivery vans that are almost always either in use or being recharged,” said Geslin. “For consumers using their EVs to get to work, pick up their kids, go to the grocery store, but mostly not using them or even charging them, time becomes the predominant cause of aging over cycling.”

The study identifies an average discharge rate sweet spot for balancing time aging and cycle aging, at least for the commercial battery they tested. Luckily, that window is in the range of realistic consumer EV driving. Carmakers could update their EV battery management software to take advantage of the new findings and to maximize battery longevity under real-world conditions.

Looking ahead

“Going forward, evaluating new battery chemistries and designs with realistic demand profiles will be really important,” said energy science and engineering postdoctoral scholar Le Xu. “Researchers can now revisit presumed aging mechanisms at the chemistry, materials, and cell levels to deepen their understanding. This will facilitate the development of advanced control algorithms that optimize the use of existing commercial battery architectures.”

The implications extend beyond batteries, the study suggests. Scientists and engineers could apply the principles to other energy storage applications, as well as to other materials and devices in physical sciences in which aging is crucial, like plastics, glasses, solar cells, and some biomaterials used in implants.

“This work highlights the power of integrating multiple areas of expertise – from materials science, control, and modeling to machine learning – to advance innovation,” Onori said.

For more information

Onori is also a senior fellow at Stanford’s Precourt Institute for Energy and an associate professor, by courtesy, of electrical engineering. Additional authors of the study are William Chueh, director of the Precourt Institute for Energy, associate professor of materials science and engineering, of energy science and engineering, and of photon science at SLAC; Devi Ganapathi, PhD ’23, Materials Science and Engineering; and Kevin Moy, PhD ’23, Energy Science and Engineering. This work was supported by the National Science Foundation Graduate Research Fellowship and the Stanford Chevron Fellowship in Energy.

Media contact

Mark Golden, Precourt Institute for Energy: (650) 724-1629, mark.golden@stanford.edu